Cov txheej txheem thiab txheej txheem ntawm cov tawv nqaij, polyurethane (PU) microfiber hluavtaws tawv thiab polyvinyl chloride (PVC) hluavtaws tawv tau muab piv, thiab cov khoom siv tau raug kuaj, piv thiab tshuaj xyuas. Cov txiaj ntsig tau pom tias nyob rau hauv cov ntsiab lus ntawm kev siv tshuab, kev ua tau zoo ntawm PU microfiber hluavtaws tawv yog zoo dua li cov tawv tawv thiab PVC hluavtaws tawv; Nyob rau hauv cov nqe lus ntawm dabtsi yog khoov kev ua tau zoo, kev ua tau zoo ntawm PU microfiber hluavtaws tawv thiab PVC hluavtaws tawv yog zoo sib xws, thiab kev khoov kev ua tau zoo yog zoo dua li cov tawv tiag tiag tom qab kev laus hauv ntub dej kub, kub kub, kev hloov pauv huab cua, thiab qhov kub thiab txias; Nyob rau hauv cov nqe lus ntawm hnav tsis kam, hnav thiab tsim kua muag kuj ntawm PU microfiber hluavtaws tawv thiab PVC hluavtaws tawv yog zoo dua li cov tawv tawv; Nyob rau hauv cov nqe lus ntawm lwm yam khoom siv, cov dej vapor permeability ntawm cov tawv tiag, PU microfiber hluavtaws tawv thiab PVC hluavtaws tawv txo qis, thiab qhov seem stability ntawm PU microfiber hluavtaws tawv thiab PVC hluavtaws tawv tom qab thermal aging yog zoo sib xws thiab zoo dua li cov tawv tawv.

Raws li ib feem tseem ceeb ntawm lub tsheb sab hauv, lub rooj zaum hauv tsheb ncaj qha cuam tshuam rau tus neeg siv kev tsav tsheb. Cov tawv nqaij, polyurethane (PU) microfiber hluavtaws tawv (tom qab no hu ua PU microfiber tawv) thiab polyvinyl chloride (PVC) hluavtaws tawv yog txhua yam siv rooj zaum ntaub.

Ntuj tawv muaj keeb kwm ntev ntawm daim ntawv thov hauv tib neeg lub neej. Vim muaj cov tshuaj lom neeg thiab triple helix qauv ntawm collagen nws tus kheej, nws muaj qhov zoo ntawm softness, hnav tsis kam, siab zog, siab nqus dej thiab dej permeability. Natural tawv feem ntau yog siv rau hauv lub rooj zaum fabrics ntawm nruab nrab-rau-high-end qauv hauv kev lag luam automotive (feem ntau cowhide), uas tuaj yeem muab cov khoom kim heev thiab kev nplij siab.

Nrog rau txoj kev loj hlob ntawm tib neeg lub neej, cov khoom ntawm cov tawv nqaij yog qhov nyuaj rau kev ua kom tau raws li cov neeg xav tau kev loj hlob. Tib neeg tau pib siv cov khoom siv tshuaj lom neeg thiab cov hau kev los hloov cov tawv nqaij, uas yog, tawv hluavtaws tawv. Lub advent ntawm PVC hluavtaws tawv tuaj yeem taug qab mus rau 20th Xyoo 1930s, nws yog thawj tiam ntawm cov khoom tawv tawv. Nws cov yam ntxwv ntawm cov khoom muaj zog, hnav tsis kam, folding kuj, acid thiab alkali tsis kam, thiab lwm yam, thiab nws yog tus nqi qis thiab yooj yim rau kev ua. PU microfiber tawv tau ua tiav hauv xyoo 1970s. Tom qab kev nce qib thiab kev txhim kho ntawm kev siv thev naus laus zis niaj hnub no, raws li hom tshiab ntawm cov khoom siv hluavtaws tawv, nws tau siv dav hauv cov khaub ncaws high-end, rooj tog zaum, pob, tsheb sab hauv thiab lwm yam. Cov yam ntxwv ntawm cov khoom siv ntawm PU microfiber tawv yog tias nws simulates cov qauv sab hauv thiab kev ntxhib los mos zoo ntawm cov tawv nqaij, thiab muaj kev ruaj khov zoo dua li tawv tawv, ntau cov khoom siv tau zoo thiab kev phooj ywg ib puag ncig.

Kev sim ib feem

PVC hluavtaws tawv

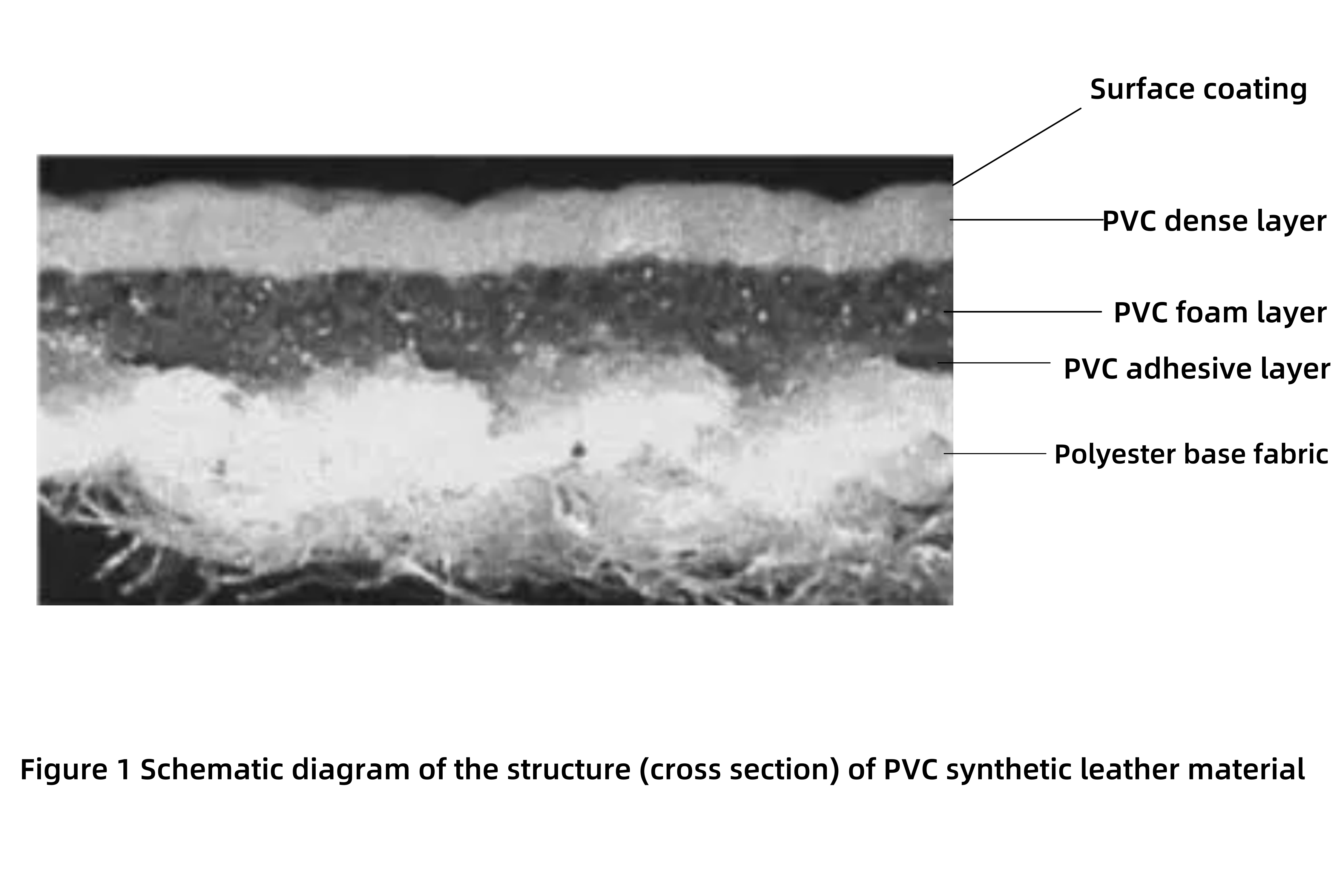

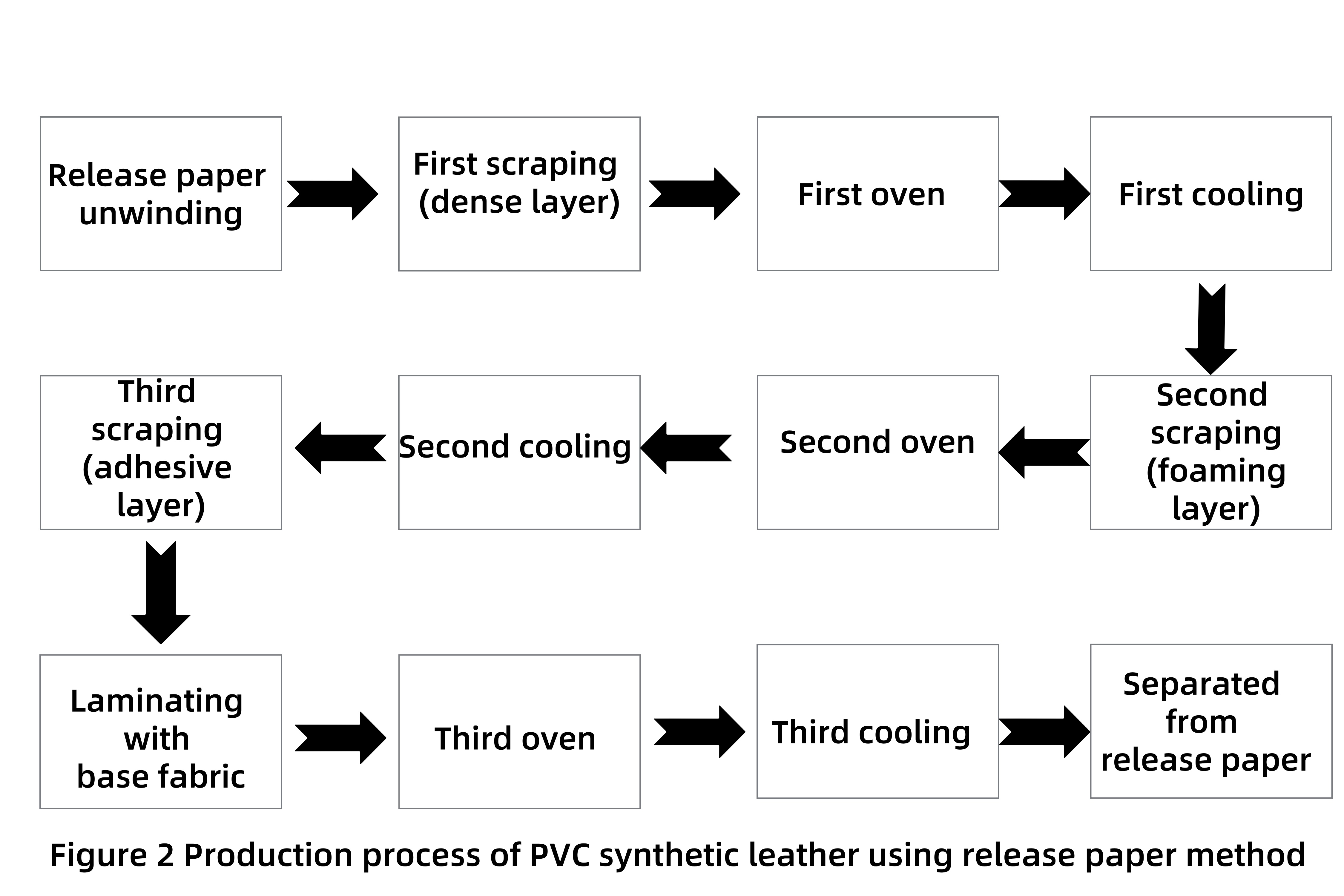

Cov khoom siv ntawm PVC hluavtaws tawv feem ntau muab faib ua Nws yog txheej txheej txheej, PVC ntom txheej, PVC ua npuas ncauj txheej, PVC nplaum txheej thiab polyester puag ntaub (saib daim duab 1). Nyob rau hauv txoj kev tso tawm daim ntawv (hloov txheej txheej), PVC slurry yog thawj zaug scraped rau thawj lub sij hawm los tsim PVC ntom txheej (nto txheej) ntawm daim ntawv tso tawm, thiab nkag mus rau thawj qhov cub rau gel plasticization thiab txias; thib ob, tom qab qhov thib ob scraping, PVC npuas txheej yog tsim los ntawm lub hauv paus ntawm PVC ntom txheej, thiab tom qab ntawd plasticized thiab txias hauv qhov cub thib ob; Thib peb, tom qab qhov thib peb scraping, PVC nplaum txheej (hauv qab txheej) yog tsim, thiab nws yog bonded nrog lub hauv paus ntaub, thiab nkag mus rau peb lub qhov cub rau plasticization thiab foaming; Thaum kawg, nws raug tshem tawm ntawm daim ntawv tso tawm tom qab txias thiab sib sau ua ke (saib daim duab 2).

Ntuj tawv thiab PU microfiber tawv

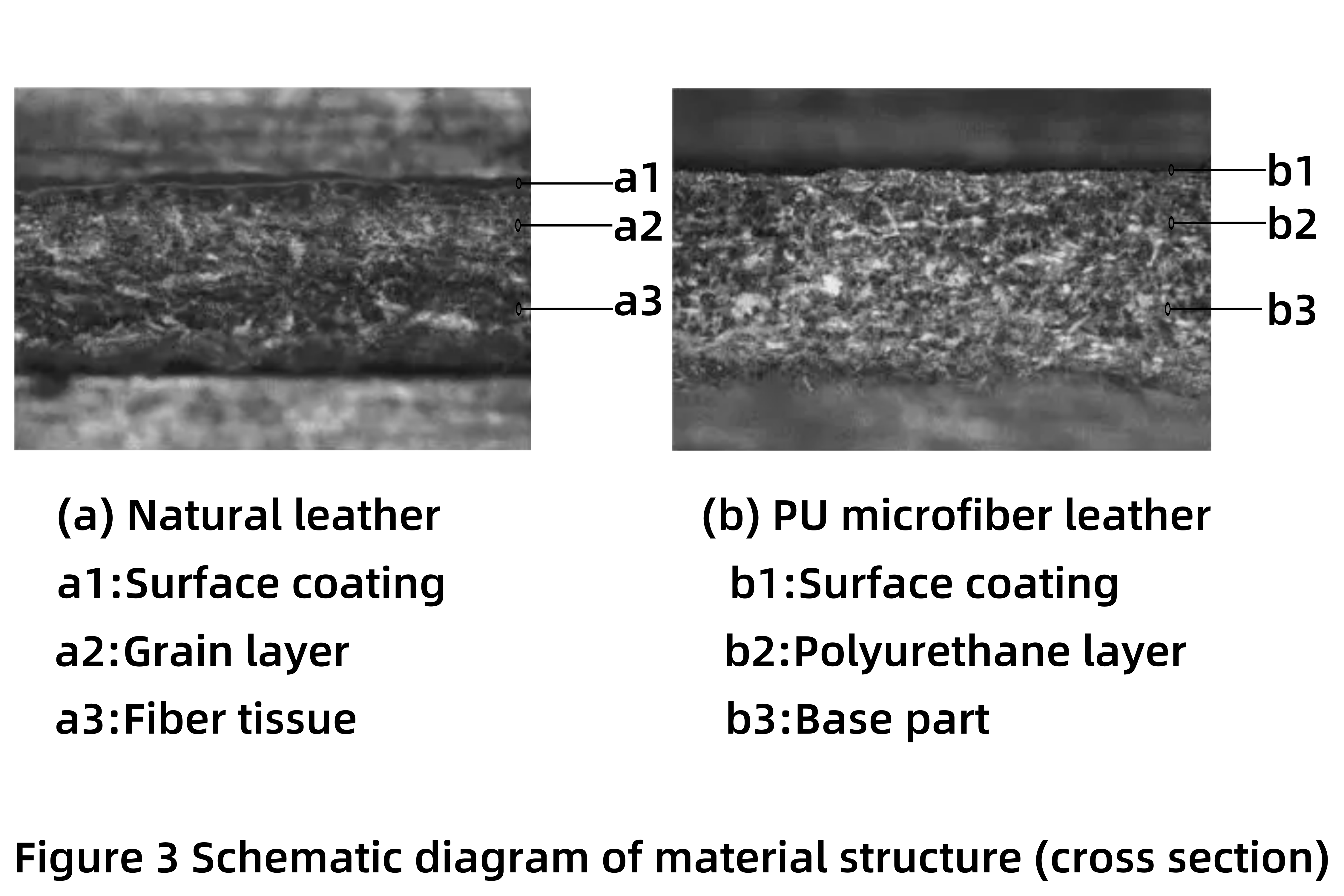

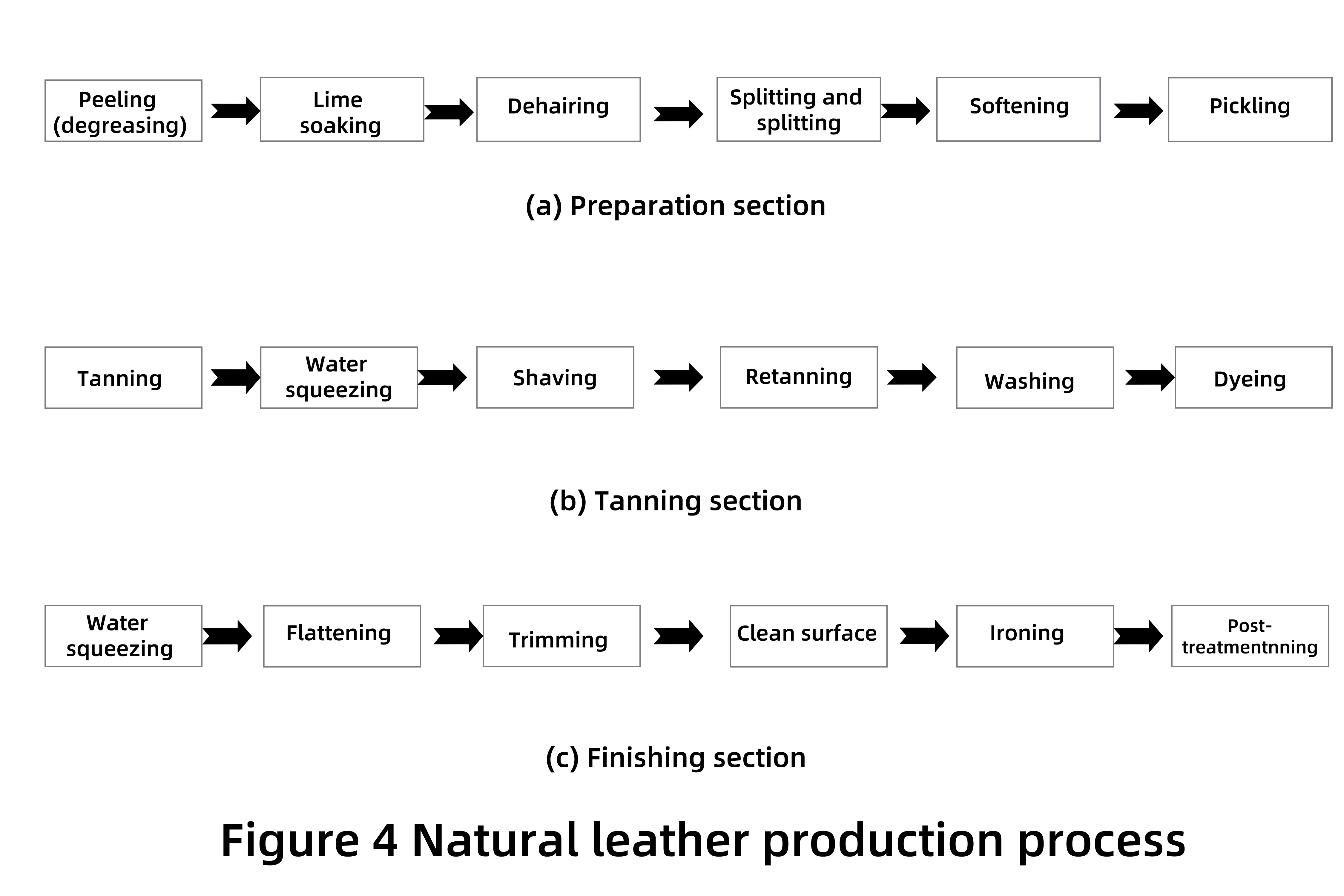

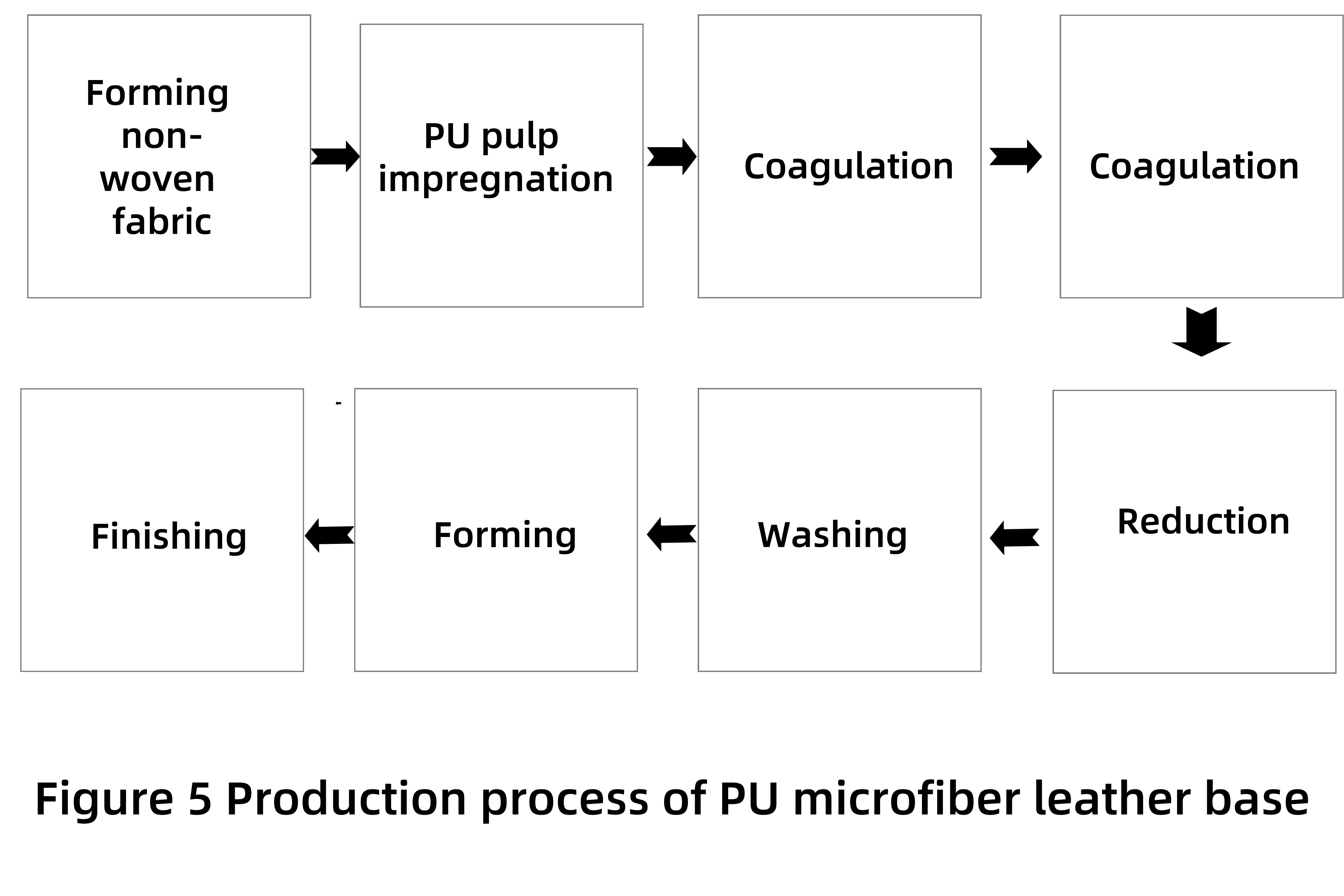

Cov khoom siv ntawm cov tawv nqaij muaj xws li txheej txheej, fiber ntau thiab txheej txheej (saib daim duab 3(a)). Cov txheej txheem tsim los ntawm cov tawv nqaij nyoos mus rau cov tawv hluavtaws feem ntau muab faib ua peb theem: kev npaj, tanning thiab tiav (saib daim duab 4). Lub hom phiaj tseem ceeb ntawm tus tsim ntawm PU microfiber tawv yog simulate natural tawv nyob rau hauv cov nqe lus ntawm cov ntaub ntawv qauv thiab zoo nkauj zoo nkauj. Cov khoom siv ntawm PU microfiber tawv feem ntau suav nrog PU txheej, puag ncig thiab txheej txheej (saib daim duab 3(b)). Ntawm lawv, lub hauv paus ib feem siv bundled microfibers nrog cov qauv zoo sib xws thiab kev ua tau zoo rau bundled collagen fibers nyob rau hauv tej tawv nqaij. Los ntawm cov txheej txheem tshwj xeeb tsis-woven nrog cov qauv peb-seem nrog pu filling cov qauv (saib Daim Duab 5).

Kev npaj ua qauv

Cov qauv yog los ntawm cov khoom siv hluav taws xob tseem ceeb hauv cov khoom siv hauv tsev. Ob qho qauv ntawm txhua yam khoom siv, tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv, yog npaj los ntawm 6 tus neeg muag khoom sib txawv. Cov qauv no yog hu ua tawv tawv 1 # thiab 2 #, PU microfiber tawv 1 # thiab 2 #, PVC hluavtaws tawv 1 # thiab 2 #. Cov xim ntawm cov qauv yog dub.

Kev ntsuam xyuas thiab tus cwj pwm

Ua ke nrog cov kev cai ntawm kev siv tsheb rau cov khoom siv, cov qauv saum toj no tau muab piv rau cov khoom siv kho tshuab, folding tsis kam, hnav tsis kam thiab lwm yam khoom siv. Cov khoom xeem tshwj xeeb thiab cov hau kev tau qhia hauv Table 1.

Table 1 Cov khoom ntsuas tshwj xeeb thiab cov txheej txheem rau kev ntsuas cov khoom siv

| Tsis muaj. | Kev faib ua haujlwm | Cov khoom kuaj | Khoom npe | Kev sim |

| 1 | Main mechanical zog | Tensile zog / elongation thaum so | Zwick tensile xeem tshuab | TS EN ISO 13934-1: TS EN ISO 13934-1 |

| Lub zog tsim kua muag | Zwick tensile xeem tshuab | TS EN ISO 3377-1: TS EN ISO 3377-1 | ||

| Static elongation / mus tas li deformation | Suspension bracket, hnyav | PV 3909 (50 N / 30 min) | ||

| 2 | Folding kuj | Folding xeem | Tawv dabtsi yog khoov tester | TS EN ISO 5402-1: 1 |

| 3 | Abrasion tsis kam | Xim ceev rau kev sib txhuam | Tawv kev sib txhuam tester | TS EN ISO 11640 Kev Tswj Xyuas Kev Nyab Xeeb |

| Pob phaj abrasion | Martindale abrasion tester | VDA 230-211 | ||

| 4 | Lwm yam khoom siv | Dej permeability | Tawv noo noo tester | TS EN ISO 14268 Kev Nyab Xeeb Kev Nyab Xeeb |

| Kab rov tav nplaim retardancy | Kab rov tav nplaim retardant ntsuas cov cuab yeej | TL. 1010 | ||

| Dimensional stability (shrinkage tus nqi) | Kub kub qhov cub, huab cua hloov chamber, kav | - | ||

| Cov ntxhiab tsw emission | Kub kub qhov cub, tsw ntxhiab khoom siv | VW 50180 |

Kev tsom xam thiab kev sib tham

Mechanical zog

Table 2 qhia cov khoom siv ntsuas cov ntaub ntawv ntawm cov tawv tiag, PU microfiber tawv thiab PVC hluavtaws tawv, qhov L sawv cev rau cov khoom siv warp kev taw qhia thiab T sawv cev rau cov khoom siv weft. Nws tuaj yeem pom los ntawm Table 2 tias hais txog lub zog tensile thiab elongation ntawm kev tawg, lub zog tensile ntawm ntuj tawv nyob rau hauv ob qho tib si warp thiab weft cov lus qhia yog siab dua li ntawm PU microfiber tawv, qhia lub zog zoo dua, thaum lub elongation ntawm tawg ntawm PU microfiber tawv yog ntau dua thiab toughness zoo dua; thaum lub zog tensile thiab elongation ntawm kev tawg ntawm PVC hluavtaws tawv yog ob qho tib si qis dua li ntawm ob cov ntaub ntawv. Nyob rau hauv cov nqe lus ntawm static elongation thiab mus tas li deformation, lub tensile lub zog ntawm tej tawv nqaij yog siab dua li ntawm PU microfiber tawv, uas qhia lub zog zoo dua, thaum lub elongation ntawm tawg ntawm PU microfiber tawv yog ntau dua thiab lub toughness yog zoo dua. Nyob rau hauv cov nqe lus ntawm deformation, qhov mus tas li deformation ntawm PU microfiber tawv yog qhov tsawg tshaj plaws nyob rau hauv ob qho tib si warp thiab weft cov lus qhia (qhov nruab nrab mus tas li deformation nyob rau hauv warp kev taw qhia yog 0.5%, thiab qhov nruab nrab deformation nyob rau hauv weft kev taw qhia yog 2.75%), qhia tau hais tias cov khoom muaj qhov zoo tshaj plaws rov ua hauj lwm tom qab stretched, uas yog zoo dua li tawv tawv thiab PVC hluavtaws. Static elongation yog hais txog qhov degree ntawm elongation deformation ntawm cov khoom nyob rau hauv kev ntxhov siab thaum lub sij hawm sib dhos ntawm lub rooj zaum npog. Tsis muaj qhov yuav tsum tau muaj tseeb hauv tus qauv thiab nws tsuas yog siv los ua tus nqi siv xwb. Nyob rau hauv cov nqe lus ntawm tearing quab yuam, qhov tseem ceeb ntawm peb cov khoom siv coj mus kuaj zoo sib xws thiab tuaj yeem ua tau raws li tus qauv yuav tsum tau ua.

Table 2 Mechanical properties test results of tiag tawv, PU microfiber tawv thiab PVC hluavtaws tawv

| Qauv | Tensile zog / MPa | Elongation ntawm tawg /% | Static elongation /% | Permanent deformation /% | Tear force / N | |||||

| L | T | L | T | L | T | L | T | L | T | |

| Tawv tawv 1 # | 17.7 ib | 16.6 | 54.4 ib | 50.7 ua | 19.0 Nws | 11.3 | 5.3 | 3.0 | 50 | 52.4 ib |

| Tawv 2 # | 15.5 ib | 15.0 Nws | 58.4 ib | 58.9 ua | 19.2 ib | 12.7 ib | 4.2 | 3.0 | 33.7 ib | 34.1 ib |

| Cov tawv nqaij tiag tiag | ≥9.3 | ≥9.3 | ≥30.0 | ≥40.0 | ≤ 3.0 | ≤4.0 | ≥25.0 | ≥25.0 | ||

| PU microfiber tawv 1 # | 15.0 Nws | 13.0 Nws | 81.4 ib | 120.0 Nws | 6.3 | 21.0 Nws | 0.5 | 2.5 | 49.7 ib | 47.6 ib |

| PU microfiber tawv 2 # | 12.9 Nws | 11.4 | 61.7 ib | 111.5 ib | 7.5 | 22.5 ib | 0.5 | 3.0 | 67.8 ib | 66.4 ib |

| PU Microfiber tawv txheej txheem | ≥9.3 | ≥9.3 | ≥30.0 | ≥40.0 | ≤ 3.0 | ≤4.0 | ≥40.0 | ≥40.0 | ||

| PVC hluavtaws tawv I # | 7.4 ib | 5.9 | 120.0 Nws | 130.5 Nws | 16.8 ib | 38.3 ib | 1.2 | 3.3 | 62.5 ib | 35.3 ib |

| PVC hluavtaws tawv 2 # | 7.9 ib | 5.7 | 122.4 ib | 129.5 ib | 22.5 ib | 52.0 Nws | 2.0 | 5.0 | 41.7 ib | 33.2 ib |

| PVC hluavtaws tawv txheem | ≥3.6 | ≥3.6 | ≤ 3.0 | ≤ 6.0 | ≥30.0 | ≥25.0 | ||||

Feem ntau, cov qauv PU microfiber tawv muaj lub zog tensile zoo, elongation ntawm kev tawg, mus tas li deformation thiab tearing quab yuam, thiab cov cuab yeej siv tau zoo dua li cov tawv tawv thiab PVC hluavtaws tawv.

Folding kuj

Cov xeev ntawm cov qauv folding kuj tau muab faib ua 6 hom, uas yog lub xeev pib (tsis muaj lub xeev), damp tshav kub laus lub xeev, tsis tshua muaj kub xeev (-10 ℃), xenon lub teeb laus lub xeev (PV1303/3P), kub kub aging xeev (100 ℃ / 168h) thiab climate alternation aging xeev (PV12 00/2). Txoj kev folding yog siv tawv dabtsi yog khoov ntsuas los kho ob qhov kawg ntawm cov qauv duab plaub nyob rau hauv qhov ntev ntawm cov kev taw qhia ntawm lub ntsuas phoo thiab qis, kom cov qauv yog 90 °, thiab rov khoov ntawm qee qhov ceev thiab lub kaum ntse ntse. Cov ntaub ntawv folding kev ua tau zoo ntawm cov tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv tau pom nyob rau hauv Table 3. Nws tuaj yeem pom los ntawm Table 3 tias cov tawv tawv tiag tiag, PU microfiber tawv thiab PVC hluavtaws tawv qauv yog tag nrho cov ntaub qhwv tom qab 100,000 zaug hauv thawj lub xeev thiab 10,000 zaug hauv lub xeev laus nyob rau hauv xenon teeb. Nws tuaj yeem tuav lub xeev zoo yam tsis muaj kab nrib pleb lossis kev ntxhov siab ua kom dawb. Hauv lwm lub xeev kev laus sib txawv, uas yog, lub xeev ntub dej kub, lub xeev kub kub, thiab kev hloov pauv huab cua ntawm PU microfiber tawv thiab PVC hluavtaws tawv, cov qauv tuaj yeem tiv taus 30,000 bending xeem. Tom qab 7,500 mus rau 8,500 kev sim khoov, cov kab nrib pleb lossis kev ntxhov siab tau pib tshwm rau hauv lub xeev ntub dej kub laus thiab kub kub laus lub xeev cov qauv ntawm cov tawv tiag, thiab qhov hnyav ntawm cov tawv nqaij ntub dej (168h / 70 ℃ / 75%) yog qis dua li ntawm PU microfiber tawv. Fiber tawv thiab PVC hluavtaws tawv (240h / 90 ℃ / 95%). Ib yam li ntawd, tom qab 14,000 ~ 15,000 qhov kev sim khoov, cov kab nrib pleb lossis kev ntxhov siab yuav tshwm sim nyob rau hauv lub xeev ntawm cov tawv nqaij tom qab huab cua hloov pauv kev laus. Qhov no yog vim qhov khoov tsis kam ntawm tawv feem ntau yog nyob ntawm lub ntuj lis txheej thiab cov qauv fiber ntau ntawm cov tawv qub, thiab nws qhov kev ua tau zoo tsis zoo li cov khoom siv hluavtaws. Raws li txoj cai, cov txheej txheem cov khoom siv rau tawv kuj qis dua. Qhov no qhia tau hais tias cov khoom siv tawv yog ntau "rhiab" thiab cov neeg siv yuav tsum tau ceev faj ntau dua lossis ua tib zoo saib xyuas thaum siv.

Table 3 Folding kev ua tau zoo ntawm cov tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv

| Qauv | Thawj lub xeev | Wet heat aging state | Tsawg kub xeev | Xenon lub teeb aging xeev | Kub kub aging xeev | Climate alternation aging state |

| Tawv tawv 1 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 168 h / 70 ℃ / 75% 8 000 zaug, cov kab nrib pleb pib tshwm, kev ntxhov siab ua kom dawb | 32 000 lub sij hawm, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 7500 lub sij hawm, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab whitening | 15 000 zaug, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab whitening |

| Tawv 2 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 168 h / 70 ℃ / 75% 8 500 zaug, cov kab nrib pleb pib tshwm, kev ntxhov siab ua kom dawb | 32 000 lub sij hawm, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 8000 zaug, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab whitening | 4000 zaug, cov kab nrib pleb pib tshwm, tsis muaj kev ntxhov siab ua kom tawv nqaij |

| PU microfiber tawv 1 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 240 h / 90 ℃ / 95% 30 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 35 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening |

| PU microfiber tawv 2 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 240 h / 90 ℃ / 95% 30 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 35 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening |

| PVC hluavtaws tawv 1 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 240 h / 90 ℃ / 95% 30 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 35 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening |

| PVC hluavtaws tawv 2 # | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 240 h / 90 ℃ / 95% 30 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 35 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening |

| Cov txheej txheem tawv tiag tiag | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 168 h / 70 ℃ / 75% 5 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | Tsis xav tau | Tsis xav tau |

| PU microfiber tawv txheej txheem yuav tsum | 100,000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 240 h / 90 ℃ / 95% 30 000 zaug, tsis muaj kab nrib pleb lossis kev ntxhov siab | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 10 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening | 30 000 zaug, tsis muaj kab nrib pleb los yog kev nyuaj siab whitening |

Feem ntau, folding kev ua tau zoo ntawm tawv, PU microfiber tawv thiab PVC hluavtaws tawv qauv yog zoo nyob rau hauv thawj lub xeev thiab xenon lub teeb aging xeev. Nyob rau hauv lub ntub dej kub laus lub xeev, tsis tshua muaj kub xeev, kub siab aging xeev thiab kev nyab xeeb kev laus lub xeev, folding kev ua tau zoo ntawm PU microfiber tawv thiab PVC hluavtaws tawv yog zoo sib xws, uas yog zoo dua li ntawm tawv.

Abrasion tsis kam

Qhov kev ntsuam xyuas kev puas tsuaj muaj xws li kev sib txhuam xim nrawm thiab kev kuaj pob phaj puas. Cov tawv tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv yog pom nyob rau hauv Table 4. Cov kev sib txhuam xim ceev cov txiaj ntsig tau pom tias cov tawv nqaij, PU microfiber tawv thiab PVC hluavtaws tawv qauv yog nyob rau hauv thawj lub xeev, deionized dej soaked xeev, alkaline hws soaked lub xeev thiab Thaum soaked nyob rau hauv 96% ethanol, cov xim yuav tsum ceev ceev 0. yog ruaj khov thiab yuav tsis ploj mus vim kev sib txhuam nto. Cov txiaj ntsig ntawm lub pob phaj abrasion kuaj pom tau tias tom qab 1800-1900 lub sij hawm hnav, cov qauv tawv muaj li 10 qhov kev puas tsuaj, uas yog qhov txawv ntawm qhov hnav tsis kam ntawm PU microfiber tawv thiab PVC hluavtaws tawv qauv (ob qho tib si tsis muaj qhov puas tsuaj tom qab 19,000 zaug hnav). Yog vim li cas rau lub qhov puas lawm yog hais tias lub grain txheej ntawm tawv yog puas tom qab hnav, thiab nws hnav tsis kam yog heev txawv los ntawm cov khoom siv hluavtaws. Yog li ntawd, tsis muaj zog hnav tsis kam ntawm tawv kuj xav kom cov neeg siv yuav tsum xyuam xim rau kev saib xyuas thaum siv.

| Table 4 Cov txiaj ntsig ntawm kev hnav tsis kam ntawm tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv | |||||

| Cov qauv | Xim ceev rau kev sib txhuam | Pob phaj hnav | |||

| Thawj lub xeev | Deionized dej soaked xeev | Alkaline hws soaked xeev | 96% ethanol soaked lub xeev | Thawj lub xeev | |

| (2000 zaug kev sib txhuam) | (500 zaug kev sib txhuam) | (100 zaug kev sib txhuam) | (5 zaug kev sib txhuam) | ||

| Tawv tawv 1 # | 5.0 | 4.5 | 5.0 | 5.0 | Txog 1900 zaug 11 qhov puas lawm |

| Tawv 2 # | 5.0 | 5.0 | 5.0 | 4.5 | Txog 1800 zaug 9 qhov puas lawm |

| PU microfiber tawv 1 # | 5.0 | 5.0 | 5.0 | 4.5 | 19 000 zaug Tsis muaj qhov chaw puas lawm |

| PU microfiber tawv 2 # | 5.0 | 5.0 | 5.0 | 4.5 | 19 000 zaug tsis muaj qhov chaw puas tsuaj |

| PVC hluavtaws tawv 1 # | 5.0 | 4.5 | 5.0 | 5.0 | 19 000 zaug tsis muaj qhov chaw puas tsuaj |

| PVC hluavtaws tawv 2 # | 5.0 | 5.0 | 5.0 | 4.5 | 19 000 zaug tsis muaj qhov chaw puas tsuaj |

| Cov txheej txheem tawv tiag tiag | ≥4.5 | ≥4.5 | ≥4.5 | ≥4.0 | 1500 zaug ntawm kev hnav thiab tsim kua muag Tsis muaj ntau tshaj 4 qhov kev puas tsuaj |

| Synthetic tawv txheem yuav tsum | ≥4.5 | ≥4.5 | ≥4.5 | ≥4.0 | 19000 zaug hnav thiab tsim kua muag Tsis muaj ntau tshaj 4 qhov kev puas tsuaj |

Feem ntau, cov tawv tawv tiag tiag, PU microfiber tawv thiab PVC hluavtaws tawv qauv txhua tus muaj kev sib txhuam zoo xim nrawm, thiab PU microfiber tawv thiab PVC tawv tawv muaj qhov hnav thiab tsim kua muag zoo dua li tawv tawv, uas tuaj yeem tiv thaiv kev hnav thiab tsim kua muag.

Lwm yam khoom siv

Cov txiaj ntsig ntawm cov dej permeability, kab rov tav nplaim retardancy, qhov ntev shrinkage thiab tsw theem ntawm cov tawv tiag, PU microfiber tawv thiab PVC hluavtaws tawv qauv yog qhia nyob rau hauv Table 5.

| Table 5 Cov txiaj ntsig ntawm lwm cov khoom siv ntawm cov tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv | ||||

| Qauv | Dej permeability / (mg / 10cm² · 24h) | Kab rov tav nplaim retardancy / (mm / min) | Dimensional shrinkage /% (120 ℃ / 168 h) | Cov ntxhiab tsw |

| Tawv tawv 1 # | 3.0 | Tsis-flammable | 3.4 | 3.7 |

| Tawv 2 # | 3.1 | Tsis-flammable | 2.6 | 3.7 |

| PU microfiber tawv 1 # | 1.5 | Tsis-flammable | 0.3 | 3.7 |

| PU microfiber tawv 2 # | 1.7 | Tsis-flammable | 0.5 | 3.7 |

| PVC hluavtaws tawv 1 # | Tsis kuaj | Tsis-flammable | 0.2 | 3.7 |

| PVC hluavtaws tawv 2 # | Tsis kuaj | Tsis-flammable | 0.4 | 3.7 |

| Cov txheej txheem tawv tiag tiag | ≥1.0 | ≤100 | ≤ 5 | ≤3.7 (deviation tau) |

| PU microfiber tawv txheej txheem yuav tsum | Tsis xav tau | ≤100 | ≤ 2 | ≤3.7 (deviation tau) |

| PVC hluavtaws tawv txheej txheem yuav tsum | Tsis xav tau | ≤100 | Tsis xav tau | ≤3.7 (deviation tau) |

Qhov sib txawv tseem ceeb hauv cov ntaub ntawv xeem yog dej permeability thiab qhov me me shrinkage. Cov dej permeability ntawm tawv yog ze li ob npaug ntawm PU microfiber tawv, thaum PVC hluavtaws tawv yuav luag tsis muaj dej permeability. Qhov no yog vim hais tias peb-dimensional network skeleton (non-woven npuag) nyob rau hauv PU microfiber tawv zoo ib yam li lub ntuj pob khoom collagen fiber qauv ntawm tawv, ob qho tib si uas muaj microporous lug, ua rau ob leeg muaj tej yam dej permeability. Tsis tas li ntawd, qhov chaw hla ntawm cov collagen fibers hauv tawv yog loj dua thiab sib npaug sib npaug, thiab qhov kev faib ua feem ntawm qhov chaw microporous yog ntau dua li ntawm PU microfiber tawv, yog li tawv muaj cov dej permeability zoo tshaj plaws. Nyob rau hauv cov nqe lus ntawm qhov me me shrinkage, tom qab tshav kub laus (120 ℃ / 1 Lub shrinkage tus nqi ntawm PU microfiber tawv thiab PVC hluavtaws tawv qauv tom qab tshav kub laus (68h) yog zoo sib xws thiab ho qis dua cov tawv tiag, thiab lawv seem stability yog zoo dua li cov tawv tiag tiag. Tsis tas li ntawd, qhov kev ntsuam xyuas ntawm kab rov tav nplaim hluav taws xob retardancy thiab tawv tawv PU tawv muaj peev xwm qhia tau hais tias cov qauv ntawm cov tawv nqaij thiab cov tawv nqaij ntawm cov tawv nqaij ntawm cov tawv nqaij thiab cov tawv nqaij ntawm cov tawv nqaij ntawm cov tawv nqaij thiab cov tawv nqaij ntawm cov tawv nqaij ntawm cov tawv nqaij thiab cov tawv nqaij ntawm cov tawv nqaij. ncav cuag cov qib zoo sib xws, thiab tuaj yeem ua tau raws li cov qauv kev cai ntawm cov nplaim hluav taws kub hnyiab thiab kev ua haujlwm tsw.

Feem ntau, cov dej vapor permeability ntawm cov tawv tawv, PU microfiber tawv thiab PVC hluavtaws tawv qauv txo qis. Cov nqi shrinkage (stabilization) ntawm PU microfiber tawv thiab PVC hluavtaws tawv tom qab tshav kub laus yog zoo sib xws thiab zoo dua li tawv tawv, thiab kab rov tav nplaim retardancy yog zoo dua li cov tawv tiag. Lub ignition thiab tsw zog yog zoo ib yam.

Xaus

Cov qauv ntoo khaub lig ntawm PU microfiber tawv zoo ib yam li cov tawv tawv. Cov txheej PU thiab lub hauv paus ntawm PU microfiber tawv sib haum rau cov txheej nplej thiab cov ntaub so ntswg fiber ntau tom kawg. Cov khoom siv qauv ntawm cov txheej ntom ntom ntom txheej, txheej txheem ua npuas dej, cov ntaub nplaum nplaum thiab cov tawv nplaum ntawm PU Microfiber tawv yog pom sib txawv.

Cov khoom zoo ntawm cov tawv nqaij yog tias nws muaj cov khoom siv zoo (lub zog tensile ≥15MPa, elongation ntawm so> 50%) thiab dej permeability. Cov khoom siv zoo ntawm PVC tawv tawv yog hnav tsis kam (tsis muaj kev puas tsuaj tom qab 19,000 lub sij hawm ntawm pob board hnav), thiab nws yog resistant rau ntau yam ib puag ncig. Cov khoom muaj kev ruaj khov zoo (nrog rau kev tiv thaiv kom ya raws thiab cua sov, kub kub, tsis tshua muaj kub, thiab alternating climates) thiab zoo seem stability (smensional shrinkage <5% nyob rau hauv 120 ℃ / 168h). PU microfiber tawv muaj cov khoom zoo ntawm ob qho tib si tawv tawv thiab PVC hluavtaws tawv. Cov txiaj ntsig ntawm cov khoom siv kho tshuab, folding kev ua tau zoo, hnav tsis kam, kab rov tav nplaim retardancy, seem stability, tsw theem, thiab lwm yam tuaj yeem ncav cuag qhov zoo tshaj plaws ntawm cov tawv tawv thiab PVC hluavtaws tawv, thiab tib lub sijhawm muaj qee yam dej permeability. Yog li ntawd, PU microfiber tawv tuaj yeem ua tau raws li daim ntawv thov ntawm cov rooj zaum hauv tsheb thiab muaj cov ntawv thov dav dav.

Post lub sij hawm: Nov-19-2024