Keeb Kwm Keeb Kwm thiab Cov Ntsiab Lus Txhais: Ob Txoj Kev Siv Tshuab

Yuav kom nkag siab qhov sib txawv ntawm ob, peb yuav tsum xub taug qab lawv cov keeb kwm kev loj hlob, uas txiav txim siab txog lawv cov tswv yim thev naus laus zis.

1. PVC Tawv: Tus Pioneer ntawm Synthetic Tawv

Keeb kwm ntawm PVC tawv hnub rov qab mus rau lub xyoo pua 19th. Polyvinyl chloride (PVC), cov khoom siv polymer, tau tshawb pom thaum ntxov li xyoo 1835 los ntawm Fab Kis tus kws kho mob Henri Victor Regnault thiab tsim los ntawm German tuam txhab Griesheim-Elektron thaum ntxov xyoo pua 20th. Txawm li cas los xij, nws qhov kev thov tiag tiag hauv tawv tawv tsis tau pib txog thaum Ntiaj Teb Tsov Rog II.

Kev tsov rog ua rau muaj kev tsis txaus, tshwj xeeb yog tawv nqaij. Cov tawv nqaij ntuj tau muab nkag rau cov tub rog feem ntau, ua rau cov pej xeem ua lag luam poob qis heev. Qhov kev xav tau tseem ceeb no tau txhawb txoj kev loj hlob ntawm lwm txoj hauv kev. Cov neeg German pioneered siv PVC coated ntawm lub hauv paus ntaub, tsim lub ntiaj teb thawj cov tawv tawv. Cov khoom siv no, nrog nws cov dej tsis zoo, ua haujlwm ntev, thiab yooj yim ntxuav, tau txais daim ntawv thov sai sai hauv thaj chaw xws li lub nra thiab cov khau khau.

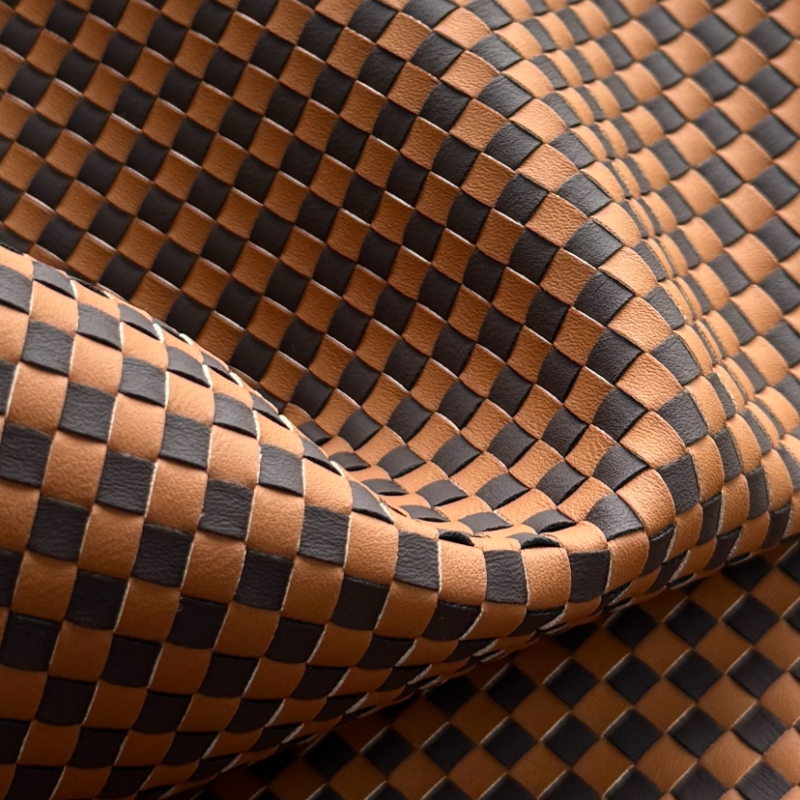

Cov ntsiab lus tseem ceeb: PVC tawv yog cov tawv zoo li cov khoom ua los ntawm txheej los yog calendering ib txheej ntawm paste-zoo li resin sib tov ntawm polyvinyl chloride resin, plasticizers, stabilizers, thiab pigments mus rau ib tug ntaub substrate (xws li knitted, woven, thiab non-woven fabrics). Cov khoom siv tom qab ntawd ua cov txheej txheem xws li gelation, foaming, embossing, thiab kho qhov chaw. Lub hauv paus ntawm cov txheej txheem no yog nyob rau hauv kev siv polyvinyl chloride resin.

2. PU Tawv: Ib qho tshiab los ze rau cov tawv tiag tiag

PU tawv tau tshwm sim kwv yees li ob xyoo caum tom qab PVC. Polyurethane (PU) chemistry tau tsim los ntawm German chemist Otto Bayer thiab nws cov npoj yaig hauv xyoo 1937 thiab tau tsim sai sai tom qab Tsov Rog Ntiaj Teb Zaum II. Kev nce qib hauv kev siv thev naus laus zis hauv xyoo 1950 thiab 1960s coj mus rau kev tsim cov tawv hluavtaws siv polyurethane.

PU hluavtaws tawv tshuab tau ntsib kev nce qib sai hauv Nyiv thiab Kaus Lim Qab Teb hauv xyoo 1970s. Tshwj xeeb, cov tuam txhab Nyij Pooj tau tsim cov ntaub ntawv microfiber (lub npe hu ua "microfiber tawv") nrog lub microstructure uas zoo li tawv tawv. Ua ke nrog cov txheej txheem polyurethane impregnation thiab txheej txheej, lawv tau tsim "microfiber PU tawv," uas nws qhov kev ua tau zoo zoo li cov tawv tawv tiag tiag thiab txawm tias nws dhau ntawm qee yam. Qhov no suav hais tias yog ib qho kev hloov pauv hauv cov tshuab hluavtaws tawv.

Cov ntsiab lus tseem ceeb: PU tawv yog cov tawv zoo li cov ntaub ntawv ua los ntawm cov ntaub hauv paus (tsis tu ncua los yog microfiber), coated los yog impregnated nrog ib txheej ntawm polyurethane resin, tom qab ziab, solidification, thiab kho deg. Lub hauv paus ntawm cov txheej txheem no yog nyob rau hauv daim ntawv thov ntawm polyurethane resin. PU resin yog inherently thermoplastic, tso cai rau kev ua tau yooj yim dua thiab cov khoom lag luam zoo dua.

Cov ntsiab lus: Keeb kwm, PVC tawv pib los ua "kev ua tsov rog thaum muaj xwm txheej ceev," daws qhov teeb meem ntawm qhov muaj. PU tawv, ntawm qhov tod tes, yog cov khoom siv thev naus laus zis, txhawm rau daws qhov teeb meem ntawm qhov zoo thiab nrhiav qhov ze-zoo tib yam ntawm tawv tawv. Lub hauv paus keeb kwm no tau cuam tshuam rau txoj kev txhim kho tom ntej thiab cov yam ntxwv ntawm ob qho tib si.

II. Core Chemical Composition thiab Production Process: Lub hauv paus ntawm qhov sib txawv

Qhov tseem ceeb tshaj plaws ntawm qhov sib txawv ntawm ob qhov lus dag hauv lawv cov txheej txheem resin, uas, zoo li lawv "genetic code," txiav txim siab tag nrho cov khoom tom qab.

1. Kev sib piv tshuaj lom neeg

PVC (Polyvinyl Chloride):

Cov khoom tseem ceeb: Polyvinyl chloride resin hmoov. Qhov no yog polar, amorphous polymer uas yog qhov nyuaj heev thiab nkig.

Ntsiab Additives:

Plasticizer: Qhov no yog "tus ntsuj plig" ntawm PVC tawv. Txhawm rau ua kom nws yooj yim thiab ua tau zoo, ntau cov yas yas (feem ntau 30% txog 60% los ntawm qhov hnyav) yuav tsum tau ntxiv. Plasticizers yog me me molecules uas embed ntawm PVC macromolecule chains, tsis muaj zog intermolecular rog thiab yog li ua rau cov ntaub ntawv yooj yim thiab plasticity. Feem ntau siv plasticizers suav nrog phthalates (xws li DOP thiab DBP) thiab cov khoom siv zoo ib puag ncig (xws li DOTP thiab citrate esters).

Thaum tshav kub kub Stabilizer: PVC yog thermally tsis ruaj khov thiab yooj yim decomposes ntawm qhov kub thiab txias, tso hydrogen chloride (HCl), ua rau cov khoom daj thiab degrade. Stabilizers xws li txhuas ntsev thiab calcium zinc yog tsim nyog los inhibit decomposition. Lwm yam: Kuj muaj xws li lubricants, fillers, pigments, thiab lwm yam.

PU (polyurethane):

Cov khoom tseem ceeb: Polyurethane resin. Nws yog tsim los ntawm cov tshuaj tiv thaiv polymerization ntawm polyisocyanates (xws li MDI, TDI) thiab polyols (polyester polyols lossis polyether polyols). Los ntawm kev kho cov qauv raw khoom thiab qhov sib piv, cov khoom kawg ntawm cov khoom, xws li hardness, elasticity, thiab hnav tsis kam, tuaj yeem tswj tau meej.

Cov yam ntxwv tseem ceeb: PU resin tuaj yeem yog qhov muag muag thiab elastic, feem ntau yuav tsum tsis muaj lossis tsawg kawg ntawm cov yas ntxiv. Qhov no ua rau PU tawv muaj pes tsawg leeg kuj yooj yim dua thiab ruaj khov dua.

Kev cuam tshuam ncaj qha ntawm cov tshuaj sib txawv: PVC qhov kev cia siab hnyav ntawm cov yas yas yog lub hauv paus ua rau ntau yam ntawm nws qhov tsis txaus (xws li kev xav nyuaj, brittleness, thiab kev txhawj xeeb ntawm ib puag ncig). PU, ntawm qhov tod tes, yog ncaj qha "engineered" kom xa cov khoom xav tau los ntawm kev siv tshuaj lom neeg, tshem tawm qhov xav tau rau cov khoom siv me me. Yog li ntawd, nws cov kev ua tau zoo dua thiab ruaj khov dua.

2. Kev sib piv txheej txheem ntau lawm

Cov txheej txheem ntau lawm yog qhov tseem ceeb rau kev ua tiav nws qhov kev ua tau zoo. Txawm hais tias ob txoj haujlwm zoo sib xws, cov ntsiab lus tseem ceeb sib txawv. PVC tawv txheej txheem (siv txheej ua piv txwv):

Cov khoom xyaw: PVC hmoov, plasticizer, stabilizer, pigment, thiab lwm yam yog tov nyob rau hauv ib tug high-ceev tov khoom los ua ib tug uniform muab tshuaj txhuam.

Txheej: PVC muab tshuaj txhuam yog sib npaug rau lub hauv paus ntaub siv lub spatula.

Gelation / Plasticization: Cov khoom coated nkag mus rau hauv qhov cub kub kub (feem ntau 170-200 ° C). Nyob rau hauv qhov kub thiab txias, PVC resin particles nqus cov plasticizer thiab yaj, tsim ib tug nruam, niaj hnub zaj duab xis txheej uas khov kho rau lub hauv paus ntaub. Cov txheej txheem no hu ua "gelation" lossis "plasticization."

Kev Kho Hniav: Tom qab txias, cov khoom siv tau dhau los ntawm cov menyuam embossing los muab ntau yam tawv nqaij (xws li lychee nplej thiab sheepskin grain). Thaum kawg, qhov ua tiav saum npoo feem ntau yog siv, xws li tshuaj tsuag-ntawm PU lacquer (piv txwv li, PVC / PU tawv tawv) txhawm rau txhim kho kev xav thiab hnav tsis kam, lossis luam ntawv thiab xim. PU tawv txheej txheem (siv cov txheej txheem ntub thiab qhuav ua piv txwv):

Cov txheej txheem tsim khoom rau PU tawv yog ntau qhov nyuaj thiab sophisticated, thiab muaj ob txoj hauv kev tseem ceeb:

Cov txheej txheem qhuav PU tawv:

Polyurethane resin yog yaj hauv cov kuab tshuaj xws li DMF (dimethylformamide) los tsim cov slurry.

Tom qab ntawd cov slurry yog siv rau ib qho kev tso tawm liner (ib daim ntawv tshwj xeeb nrog cov qauv nto).

Cov cua kub evaporates cov kuab tshuaj, ua rau cov polyurethane solidify rau hauv ib zaj duab xis, tsim cov qauv ntawm qhov tso tawm liner.

Lwm sab yog ces laminated rau ib lub hauv paus ntaub. Tom qab kev laus, cov ntaub ntawv tso tawm yog tev tawm, ua rau PU tawv nrog cov qauv muag.

Cov txheej txheem ntub dej PU tawv (hauv paus):

Polyurethane resin slurry yog siv ncaj qha mus rau lub hauv paus ntaub.

Tom qab ntawd cov ntaub yog immersed nyob rau hauv dej (DMF thiab dej yog miscible). Cov dej ua raws li coagulant, rho tawm DMF los ntawm slurry, ua rau cov polyurethane resin solidify thiab precipitate. Thaum lub sij hawm tus txheej txheem no, polyurethane tsim ib tug ntxeem tau microsphere zoo li cov qauv uas muaj roj, muab cov tawv nqaij ntub dej zoo heev noo noo thiab breathability, thiab ib tug heev mos thiab plump xav, zoo kawg li zoo li cov tawv tiag tiag.

Qhov tshwm sim ntub-ntev tawv semi-tiav cov khoom feem ntau dhau los ua cov txheej txheem qhuav rau kev kho kom zoo.

Kev cuam tshuam ncaj qha ntawm cov txheej txheem sib txawv: PVC tawv tsuas yog tsim los ntawm lub cev yaj molding, uas ua rau cov qauv ntom ntom. PU tawv, tshwj xeeb tshaj yog los ntawm cov txheej txheem ntub dej, tsim kom muaj qhov ntxeem tau, sib cuam tshuam daim txhuam cev. Qhov no yog qhov tseem ceeb ntawm kev ua kom zoo dua qub uas ua rau PU tawv zoo dua li PVC hauv cov ntsiab lus ntawm breathability thiab hnov.

III. Comprehensive Performance Comparison: Paub meej tias qhov twg zoo dua

Vim muaj cov chemistry sib txawv thiab cov txheej txheem ntau lawm, PVC thiab PU tawv pom qhov sib txawv tseem ceeb hauv lawv lub cev.

- Xav thiab Softness:

- PU tawv: mos thiab elastic, nws ua raws li lub cev nkhaus zoo dua, muab nws zoo ib yam li tawv tawv.

- PVC tawv: Cov tawv tawv thiab tsis muaj elasticity, nws yooj yim creases thaum khoov, muab nws zoo li yas. - Breathability thiab Moisture Permeability:

- PU tawv: Muaj kev ua pa zoo heev thiab noo noo permeability, ua kom tawv nqaij qhuav thaum hnav thiab siv, txo qhov kev xav ntawm qhov hnyav.

- PVC Tawv: Muaj kev ua pa tsis zoo thiab noo noo permeability, uas tuaj yeem ua rau tawm hws, dampness, thiab tsis xis nyob tom qab siv ntev lossis hnav.

- Abrasion thiab Folding Resistance:

- PU tawv: Muaj kev puas tsuaj zoo thiab folding tsis kam, tiv taus qee qhov kev sib txhuam thiab khoov, thiab tsis cuam tshuam rau hnav lossis tawg.

- PVC Tawv: Muaj qhov tsis zoo rau kev puas tsuaj thiab folding tsis kam, thiab nws tuaj yeem hnav thiab tawg tom qab siv mus ntev, tshwj xeeb tshaj yog nyob rau hauv cov cheeb tsam uas nquag folding thiab kev sib txhuam.

- Hydrolysis Resistance:

- PU tawv: Muab cov dej tsis zoo hydrolysis, tshwj xeeb tshaj yog polyester-based PU tawv, uas yog nquag hydrolysis nyob rau hauv ib puag ncig ntub, uas ua rau degradation ntawm cov khoom siv.

- PVC Tawv: Muab cov tshuaj hydrolysis zoo heev, yog qhov hloov tau zoo rau qhov chaw ntub dej, thiab tsis yooj yim puas los ntawm hydrolysis. - Kub Resistance:

- PU tawv: Nws nyiam lo ntawm qhov kub thiab txias thiab tawv ntawm qhov kub qis. Nws yog rhiab heev rau qhov kub hloov pauv thiab muaj qhov nqaim ua haujlwm kub ntau.

- PVC Tawv: Nws muaj qhov kub thiab txias zoo dua thiab tswj kev ua haujlwm ruaj khov tshaj qhov kub ntau, tab sis nws kuj muaj kev pheej hmoo ntawm brittleness ntawm qhov kub thiab txias.

- Environmental Performance:

- PU tawv: Nws yog biodegradable dua li PVC tawv. Qee cov khoom yuav muaj me me ntawm cov organic solvent residues, xws li DMF, thaum lub sij hawm tsim khoom, tab sis nws tag nrho ib puag ncig kev ua tau zoo kuj zoo.

- PVC Tawv: Nws tsis tshua muaj tus phooj ywg ib puag ncig, muaj cov tshuaj chlorine. Qee cov khoom yuav muaj cov khoom tsis zoo xws li cov hlau hnyav. Thaum lub sijhawm tsim khoom thiab siv, nws tuaj yeem tso cov pa phem, uas yuav muaj qee yam cuam tshuam rau ib puag ncig thiab tib neeg kev noj qab haus huv.

Qhov tsos thiab xim

- PU Tawv: Nws los ntawm ntau yam xim vibrant, nrog cov xim zoo thiab tsis yooj yim rau ploj. Nws qhov kev ntxhib los mos thiab cov qauv muaj ntau haiv neeg, thiab nws tuaj yeem ua raws li ntau yam tawv textures, xws li cowhide thiab sheepskin, thiab tseem tuaj yeem tsim nrog cov qauv tshwj xeeb thiab cov qauv tsim kom tau raws li cov kev xav tau sib txawv. - PVC tawv: Kuj muaj ntau yam xim, tab sis me ntsis qis dua PU tawv ntawm cov xim vividness thiab stability. Nws qhov kev ntxhib los mos yog qhov yooj yim, feem ntau yog du lossis nrog cov embossing yooj yim, ua rau nws nyuaj rau kev ua tiav qhov zoo ntawm PU tawv.

Lub neej ntev

- PU tawv: Nws lub neej feem ntau yog 2-5 xyoos, nyob ntawm ib puag ncig thiab kev siv ntau zaus. Nrog rau kev siv thiab kev saib xyuas, PU tawv khoom tuav lawv cov tsos thiab kev ua tau zoo.

- PVC tawv: Nws lub neej luv luv, feem ntau 2-3 xyoos. Vim nws cov khoom siv tsis zoo, nws ua rau muaj kev laus thiab kev puas tsuaj nrog kev siv ntau zaus lossis ib puag ncig hnyav.

Nqi thiab Nqe

- PU tawv: Nws tus nqi siab dua PVC tawv, kwv yees li 30% -50% siab dua. Nws tus nqi sib txawv nyob ntawm seb yam xws li cov txheej txheem ntau lawm, raw khoom zoo, thiab hom. Feem ntau, nruab nrab mus rau high-end PU tawv khoom kim dua.

- PVC tawv: Nws cov nqi qis, ua rau nws yog ib qho ntawm cov khoom siv hluavtaws uas pheej yig tshaj plaws hauv khw. Nws tus nqi kom zoo dua ua rau nws siv dav hauv cov khoom lag luam raug nqi.

Cov ntsiab lus ua haujlwm:

PVC tawv qhov zoo muaj xws li hnav tsis kam, siab hardness, tsis tshua muaj nqi, thiab cov txheej txheem ntau lawm. Nws yog ib qho zoo heev "cov khoom siv ua haujlwm."

PU tawv qhov zoo muaj xws li kev xav mos, breathability, ya raws permeability, txias thiab laus tiv taus, zoo heev lub cev, thiab ib puag ncig tus phooj ywg. Nws yog ib qho zoo heev "cov ntaub ntawv kev paub," tsom mus rau kev ua kom zoo nkauj thiab ua kom zoo tshaj qhov kev xav ntawm cov tawv tiag tiag.

IV. Application Scenario: Sib txawv ntawm Kev Ua Haujlwm

Raws li cov yam ntxwv ntawm kev ua tau zoo saum toj no, ob qho tib si ib txwm muaj qhov sib txawv thiab kev faib ua haujlwm hauv kev ua lag luam. Kev siv tseem ceeb ntawm PVC tawv:

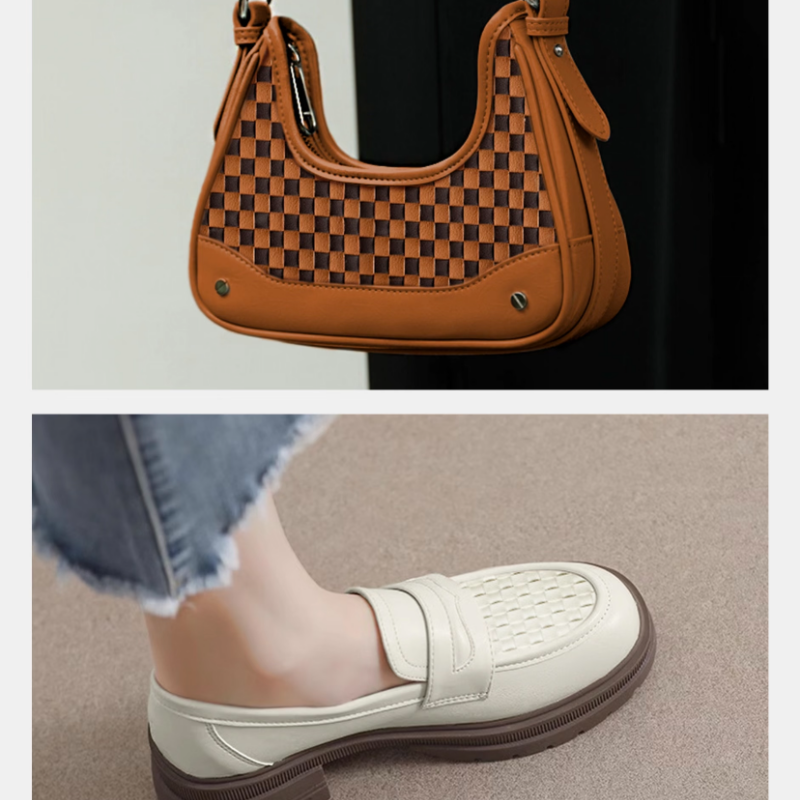

Luggage and Handbags : Tshwj xeeb yog cov tawv tawv thiab hnab tes uas yuav tsum tau muaj cov duab ruaj khov, nrog rau cov hnab mus ncig thiab hnab ev khoom uas yuav tsum tau hnav tsis kam.

Cov Khoom Siv Khau: Feem ntau yog siv rau hauv qhov chaw tsis sib cuag xws li cov thom khwm, sab sauv, thiab hauv ob sab phlu, nrog rau cov khau khiab qis qis thiab cov khau ua haujlwm.

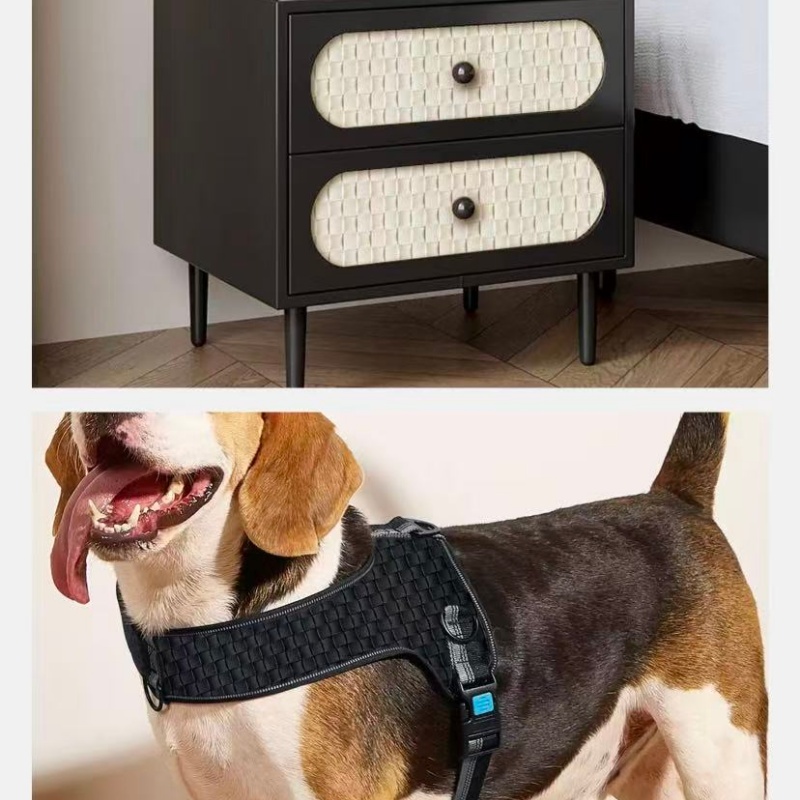

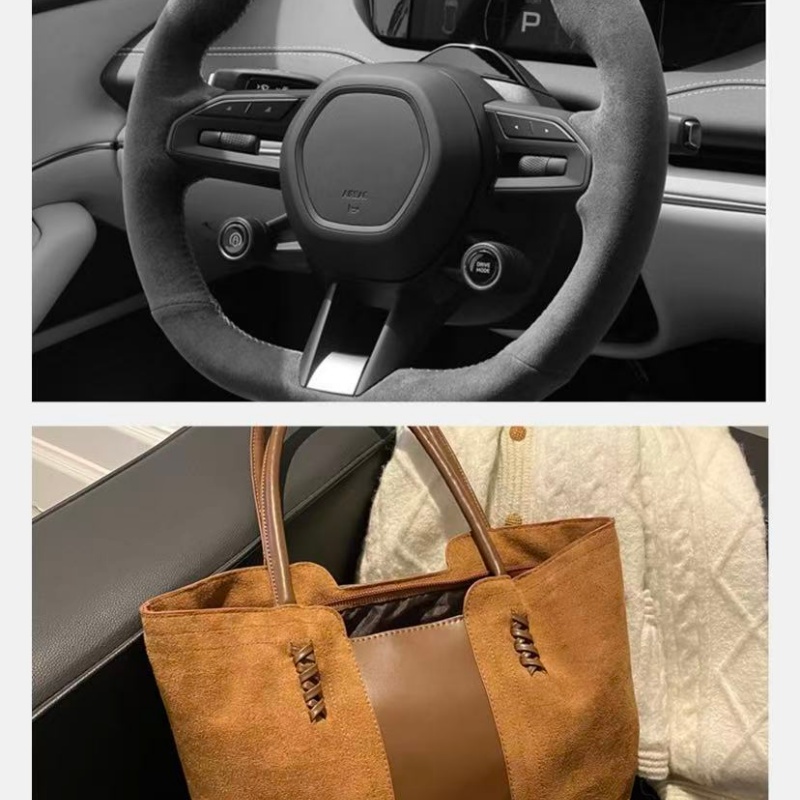

Rooj tog thiab Kho kom zoo nkauj: Siv rau ntawm qhov chaw tsis sib cuag xws li nraub qaum, sab, thiab hauv qab ntawm lub rooj zaum thiab cov rooj zaum, nrog rau hauv kev thauj mus los rau pej xeem (tsheb npav thiab subway) cov rooj zaum, qhov uas nws tsis tshua muaj hnav tsis kam thiab tus nqi qis. Cov ntaub thaiv phab ntsa, pem teb npog, thiab lwm yam Automotive interiors: Maj mam hloov los ntawm PU, nws tseem siv tau rau qee cov qauv qis lossis hauv qhov tsis tshua muaj qhov tseem ceeb xws li lub qhov rooj vaj huam sib luag thiab lub cev mats.

Cov khoom lag luam: Cov cuab yeej hnab, tiv thaiv npog, ntsuas npog, thiab lwm yam.

Kev siv tseem ceeb ntawm PU tawv:

Khau Khoom: Lub khw muag khoom tseem ceeb. Siv nyob rau hauv lub Upper ntawm khau ntaub, xws li khau, thiab khau tawv vim nws muab zoo breathability, softness, thiab ib tug stylish saib.

Khaub ncaws thiab zam: tawv tsho, tawv ris, tawv tiab, hnab looj tes, thiab lwm yam. Nws zoo heev drape thiab kev nplij siab ua rau nws nyiam nyob rau hauv kev lag luam khaub ncaws.

Cov rooj tog zaum thiab cov rooj tog zaum hauv tsev: Cov khoom siv hluavtaws tawv zoo heev, cov rooj zaum noj mov, cov rooj zaum hauv txaj, thiab lwm qhov chaw uas tuaj yeem cuam tshuam ncaj qha rau lub cev. Microfiber PU tawv yog dav siv nyob rau hauv cov khoom kim heev lub rooj zaum tsheb, kauj log, thiab dashboards, muab ib tug ze-tiag tiag tawv kev.

Lub hnab ntim khoom thiab cov khoom siv: Cov hnab ntim siab kawg, hnab nyiaj, siv, thiab lwm yam. Nws zoo nkauj zoo nkauj thiab zoo nkauj tuaj yeem tsim cov nyhuv tiag tiag.

Cov Khoom Siv Hluav Taws Xob: Siv rau hauv lub hnab laptop, rooj plaub lub mloog pob ntseg, cov iav tsom iav, thiab lwm yam., ntsuas kev tiv thaiv thiab kev zoo nkauj.

Kev ua lag luam Positioning:

PVC tawv tuav tuav txoj haujlwm ruaj khov hauv kev lag luam qis kawg thiab hauv cov khoom lag luam uas xav tau kev hnav tsis kam. Nws tus nqi-kev ua tau zoo piv yog unmatched.

PU tawv, ntawm qhov tod tes, dominates nruab nrab-rau-high-end kev ua lag luam thiab txuas ntxiv cam rau high-end lag luam yav tas los dominated los ntawm cov tawv tiag tiag. Nws yog qhov kev xaiv tseem ceeb rau cov neeg siv khoom hloov kho dua tshiab thiab ua lwm txoj hauv kev tawv tawv.

V. Nqe thiab Kev Lag Luam Kev Lag Luam

Nqe:

Tus nqi tsim khoom ntawm PVC tawv yog qis dua li ntawm PU tawv. Qhov no feem ntau yog vim tus nqi qis ntawm cov khoom siv raw xws li PVC resin thiab plasticizers, nrog rau kev siv hluav taws xob tsawg thiab cov txheej txheem tsim khoom yooj yim. Yog li ntawd, tus nqi ntawm cov tawv PVC tiav lawm feem ntau tsuas yog ib nrab lossis ib feem peb ntawm cov tawv PU.

Kev lag luam Trends:

PU tawv txuas ntxiv nthuav dav, thaum PVC tawv tuav tsis tu ncua: Thoob ntiaj teb, tshwj xeeb tshaj yog nyob rau hauv cov teb chaws tsim, PU tawv yog tsis tu ncua eroding PVC tawv cov tsoos kev ua lag luam feem ntau vim yog nce stringent ib puag ncig kev cai (xws li EU REACH kev cai txwv phthalates) thiab nce cov neeg siv khoom xav tau cov khoom zoo thiab kev nplij siab. PVC tawv txoj kev loj hlob feem ntau yog concentrated nyob rau hauv lub teb chaws tsim thiab nyob rau hauv tsis tshua muaj nqi-rhiab sectors. Kev tiv thaiv ib puag ncig thiab kev txhim kho kom ruaj khov tau dhau los ua lub zog tseem ceeb:

Bio-based PU, dej-raws li PU (tsis muaj kuab tshuaj), plasticizer-free PVC, thiab eco-friendly plasticizers tau dhau los ua kev tshawb fawb thiab kev loj hlob hotspots. Cov tswv lag luam tseem tau nce qhov tseem ceeb ntawm cov khoom siv rov ua dua tshiab.

Microfiber PU tawv (microfiber tawv) yog cov qauv yav tom ntej:

Microfiber tawv siv cov ntaub microfiber puag nrog cov qauv zoo ib yam li collagen fibers ntawm cov tawv tawv tiag tiag, muab kev ua tau zoo uas ua tau zoo los sis tseem tshaj tawv tawv. Nws yog lub npe hu ua "thib peb tiam ntawm cov tawv nqaij tawv." Nws sawv cev rau lub pinnacle ntawm hluavtaws tawv tshuab thiab yog ib tug tseem ceeb txoj kev loj hlob kev taw qhia rau high-end kev ua lag luam. Nws yog dav siv hauv high-end automotive interiors, khau kis las, khoom kim heev, thiab lwm yam.

Functional Innovation:

Ob leeg PVC thiab PU tab tom tsim cov yam ntxwv ua haujlwm xws li tshuaj tua kab mob, pwm-pov thawj, nplaim-retardant, UV-resistant, thiab hydrolysis-resistant kom tau raws li qhov xav tau ntawm cov ntawv thov tshwj xeeb.

VI. Yuav ua li cas paub qhov txawv ntawm PVC tawv los ntawm PU tawv

Rau cov neeg siv khoom thiab cov neeg yuav khoom, kev paub txog kev txheeb xyuas yooj yim yog qhov ua tau zoo heev.

combustion Method (Qhov tseeb tshaj plaws):

PVC Tawv: Yooj yim rau ignite, extinguishes tam sim ntawd thaum tshem tawm ntawm nplaim taws. Lub hauv paus ntawm nplaim taws yog ntsuab thiab muaj zog, pungent tsw ntawm hydrochloric acid (xws li hlawv yas). Nws hardens thiab blackens tom qab hlawv.

PU tawv: Flammable, nrog cov nplaim daj. Nws muaj cov ntxhiab tsw zoo ib yam li cov ntaub plaub lossis cov ntawv hlawv (vim muaj cov ester thiab cov amino pawg). Nws softens thiab ua nplaum tom qab hlawv.

Nco tseg: Txoj kev no tuaj yeem pom

PVC tawv thiab PU tawv tsis yog ib qho teeb meem ntawm "zoo" piv rau "phem." Hloov chaw, lawv yog ob yam khoom tsim los ntawm cov kev xav tau ntawm cov sijhawm sib txawv thiab kev nce qib thev naus laus zis, txhua tus muaj nws tus kheej tsim nyog thiab muaj peev xwm siv tau.

PVC tawv sawv cev qhov kawg sib npaug ntawm tus nqi thiab kav ntev. Nws tseem muaj zog nyob rau hauv cov ntawv thov uas qhov kev nplij siab thiab kev ua haujlwm ib puag ncig yog qhov tseem ceeb, tab sis qhov hnav tsis kam, dej tsis kam, thiab tus nqi qis yog qhov tseem ceeb. Nws lub neej yav tom ntej yog nyob rau hauv kev hais txog nws qhov kev pheej hmoo ntawm ib puag ncig thiab kev noj qab haus huv los ntawm ib puag ncig tus phooj ywg plasticizers thiab kev nce qib thev naus laus zis, yog li tuav nws txoj haujlwm ua cov khoom siv.

PU tawv yog qhov kev xaiv zoo tshaj plaws rau kev nplij siab thiab kev tiv thaiv ib puag ncig. Nws sawv cev rau lub ntsiab kev loj hlob ntawm hluavtaws tawv. Los ntawm kev nruam kev thev naus laus zis, nws tau dhau los ntawm PVC hauv cov ntsiab lus ntawm kev xav, ua pa, lub cev muaj zog, thiab kev ua haujlwm ib puag ncig, dhau los ua lwm txoj hauv kev rau cov tawv tawv thiab txhim kho cov khoom siv zoo. Microfiber PU tawv, tshwj xeeb, yog qhov muag tsis pom cov kab ntawm hluavtaws thiab tawv tawv, qhib cov ntawv thov tshiab high-end.

Thaum xaiv cov khoom lag luam, cov neeg siv khoom thiab cov neeg tsim khoom yuav tsum tsis txhob sib piv tus nqi tab sis ua qhov kev txiav txim siab raws li cov khoom siv kawg, cov kev cai tswj hwm hauv lub hom phiaj kev lag luam, hom kev cog lus ib puag ncig, thiab cov neeg siv kev paub. Tsuas yog los ntawm kev nkag siab txog lawv qhov sib txawv hauv qab no tuaj yeem ua qhov kev xaiv zoo tshaj plaws thiab tsim nyog tshaj plaws. Nyob rau yav tom ntej, raws li cov ntaub ntawv thev naus laus zis nce qib, peb yuav pom "thib plaub- thiab thib tsib-tiam" cov tawv tawv nrog kev ua tau zoo dua thiab muaj kev nyab xeeb dua ib puag ncig. Txawm li cas los xij, ntau tshaj li ib nrab-xyoo pua-ntev kev sib tw thiab kev sib koom ua ke ntawm PVC thiab PU yuav nyob twj ywm ib qho tseem ceeb hauv keeb kwm ntawm kev tsim cov ntaub ntawv.

Post lub sij hawm: Sep-12-2025